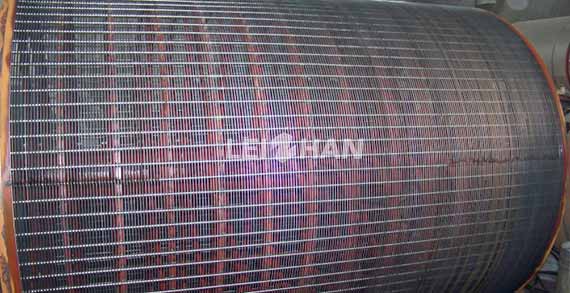

Chinese Paper Mill Cylinder Mould

As the pulp flows into the cylinder mould, the molded cylinder rotates partially submerged in the pulp. This rotation serves to evenly distribute the pulp over the surface of the mesh, allowing for optimal fiber deposition. As the cylinder mould continues to rotate, the fibers mat and bond together, creating a continuous sheet of wet paper. Once enough fiber has accumulated on the mesh, the sheet is formed and prepared for further processing.

The cylinder mould ensures even fiber distribution, leading to consistent sheet characteristics and quality. This uniformity is crucial for achieving desired paper properties. By continuously forming sheets, cylinder moulds enhance the productivity of paper making operations. Their ability to produce paper in large volumes contributes to the overall efficiency of the paper mill.

The cylinder mould is an indispensable component of the paper making process, crucial for forming high-quality paper sheets efficiently and consistently. Any interested please contact me for more information!

Email: whiteboardpapermachine@gmail.com